Building a Fuel Polish System

This page talks about the inspiration, design, construction and operation of a fuel polishing system to keep the diesel fuel clean.

The problem

On Halloween weekend 2010 Debbie and I cruised to an overnight raft-up in Town Creek. The plan was to get back home in time to hand out treats to the kids. I started the return trip back to the dock early enough for this.

I got underway. Winds were light so I started the engine. I put it into gear and increased RPMs to cruising speed. Then the engine quit. I checked and didn't see anything wrong. I started it again. It ran at low RPMs but as soon as I increased to normal cruising speed it quit. After a few tries I discerned the pattern of running fine at low speed but quitting at high. I surmised that it was a fuel starvation issue. I limped back to the dock.

Not surprisingly we returned well after dark. The trick -or- treating had finished long before we got home.

Indeed, the issue turned out to be fuel starvation issues due to dirty and clogged filters. The Racor filter had deteriorated to the point that the paper pleats had separated and allowed impurities to pass. It had not ben changed in a while. The little engine filter was intact but almost completely clogged. I was basically one filter away from expensive injector pump repairs.

Shown above is the dirty filter on the left and its replacement sitting to the right.

After some discussion on the Wooden Boat Forum and with friends I determined that the filters need to be replaced yearly whether or not they appear to be in good shape. I added this to my preventive maintenance schedule.

While renewing the filters I also purged the system of dirty fuel. I removed a lot of dirty black diesel from the Racor filter housing. I was expecting the diesel in the tank to be as dirty. I started removing fuel from the tank but soon found it to be relatively clean. Most of the dirty fuel was queued up in the filter system.

Clearly the current system is inadequate in some respects but what is to be done to prevent future occurrences?

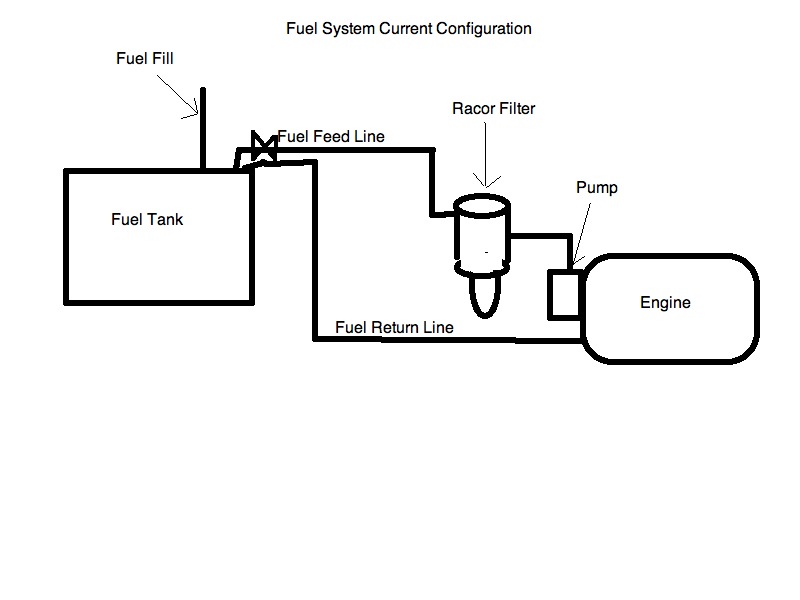

The current configuration (as of 10-31-2010) has a fuel pump pulling fuel through the Racor filter and pushing it to the primary engine fuel filter then through the injectors to cool them and back to the tank. It circulates the fuel and cleans it in the process. But this system is not well suited to cleaning the entire tank on a regular basis.

Design

I did some research. I came across a website: S/V Strider. In particular he has a page on fuel polishing: Fuel Polishing. I had some more discussion on the Wooden Boat Forum and obtained some recommendations from Roger Long. I owe special thanks to Roger and to the folks on the Wooden Boat Forum for their helpful advice.

In particular I learned:

- It would be a mistake to build a portable fuel polish system. A portable system is less convenient and messier which lends itself to less frequent use.

- One can be built in as new construction or alteration to also serve as a backup pump.

- It can be built fairly cheaply using quality parts.

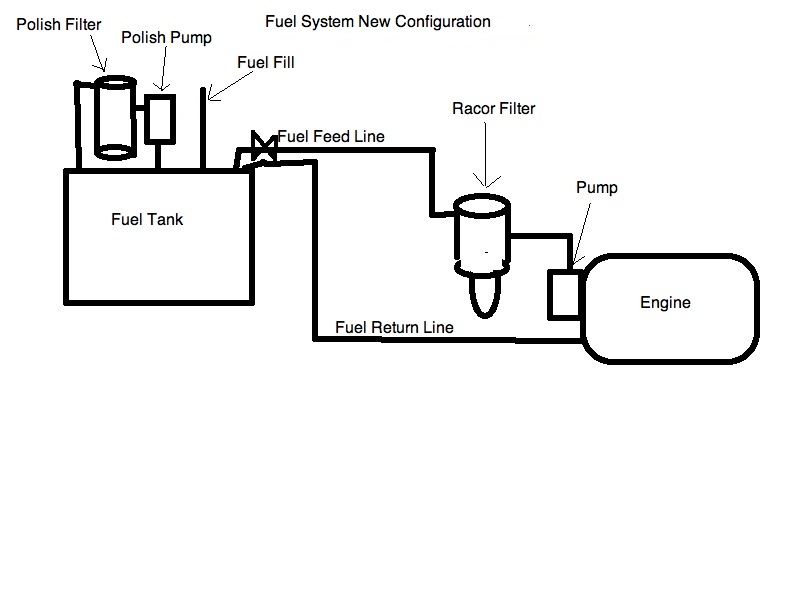

After much pondering of design options I came up with the system shown below. The fuel polish section is completely independent of the existing fuel system so there is really no possibility of side effects or interference with the engine fuel system. I wanted to have the pump act as a backup but I could not see an easy way to accomplish that. Instead I wanted to get a working system quickly.

Here is the new configuration. It shows a separate and independent filter and pump circuit for polishing the fuel.

Construction

|

Here is a Walbro FRB-22 fuel pump. It is nominally capable of circulating the entire contents of the fuel tank once per hour. |

|

Here is a Shelco RHS-80 316L water filter housing. This uses the same type of filter that Roger's setup has. I added reducer fittings to get the inlet and outlet down to 1/4". The cashier at West Marine remarked that it seemed strange to be doing such a large reduction. |

Here is a home built fuel pickup. I built this of brass fittings. I wondered about whether diesel would interact with the brass. I will inspect the fittings later to see if there is any issue.

Why home grown? Try as I might I could not find anyone selling a fuel pickup with the possible exception of Moeller Marine's P/N 033500-24. This might have worked but I wanted all metal. On the Wooden Boat Forum some folks recommended that I build my own.

Here I found the copper tube just fit into the barbed end. I sweated solder in to make a secure connection. This is a bit unusual but I don't see any real issues with this. |

|

|

Here is the fuel return. I fashioned this from a bulkhead fitting and a barbed elbow. |

It was a good time to install a second inspection port in the diesel fuel tank. I had put this on my bucket list back in 2009 when I installed the new engine. I ran into some difficulties when installing the port. After drilling the bolt holes I discovered that the cover did not fit. The bolt holes were slightly too far apart. I had to carefully file the holes in the cover until it fit. Fortunately it wasn't too far off.

By the time I got this far it was dark and I was extremely tired. The next step seemed easy but it was best to quit for the day.

Next the question of where to put the fittings in came up. I decided to put them in the port itself. This avoided the need to cut additional holes in the steel. Also the holes in the aluminum cover were much easier to cut and formed a better seal with the fittings than similar holes in the steel would have been. Also there wasn't much room to drill straight down for a hole in the steel. This might not be entirely kosher but it works. I used a lot of Rector Seal #5 to insure there would be no leaks when the boat is healed.

|

It took another whole afternoon to install the fittings. Also I was intterupted at points by rain. I used some of the 1/4 fuel tube to make a temporary cap. Then it was time to quit for the day. The idea is to make the stopping points in the project so that I can go sailing in the meantime between steps. Later I realized that it was better to put the nuts of the bulkhead fittings on top rather than on bottom. If for some reason vibration caused the nuts to work loose the barbed hose fittings would still be there to hold the body of the fitting in place. On the other hand if the nut was below the plate it could work loose and drop into the bottom of the fuel tank undetected. Yearly inspection of this is in order. |

|

Now I moved on to the layout and placement of the pump and filter. I wanted an easy to access point with short fuel lines to the fuel tank. I determined that the back of the lazarette made the best location for this. The back board provides a solid foundation for securely mounting the componnents. Not really shown but the filter rests on a custom made cradle that conforms to its shape. This plus a Shelco bracket secure the filter in place against any sort of eventuality. |

Here the filter and pump are mounted, wired and plumbed. The whole assembly is securely mounted to the bulkhead with screws and epoxy. This position allows me to go down in the lazarette to access the rear of the engine and the propeller shaft. To change the filter I just loosen the hose clamp and the filter nut. Also there is room below to place a drip pan to contain any spillage. |

|

In the course of wiring the system up to the electrical supply I found these swallow eggs. Basically I had left a nice little hole when I removed the broken Autohelm. I went sailing several times with these eggs here but kept the cover closed over the Edson worm gear. Each time the mother bird returned. The eggs later hatched and all but one of the chicks grew up and flew away. Then I cleaned out the nest and plugged the hole up.

I completed the installation by wiring the fuel pump to an on/off switch on the house panel.

Operation

I powered up the fuel polish system. At first the pump was noisy. But it got quieter after it had time to pull fuel into the filter and through the pump. It drew about 1 amp of current while running. The pump makes a ticking sound as it runs and does not sound like it is struggling. It's loud enough that I can tell it is running while under sail but it is not objectionable. I will plan on running this for about one hour for each day I sail. This should take most of the filtering load off the engine filter system.